The famous physicist Lord Kelvin once observed that a thing can not be understood until it is measured and assigned numbers. Measurement represents the properties of something, thus it is only by measurement one can achieve his/her goal. Radiofrequency or RF is one of the most important technologies in modern society. This technology, widely known as wireless, is the usage of the electromagnetic wave in the range of 3Hz and 300GHz.

Radio technology has nowadays spread to become a mass communication system and entertainment and relaxation instrument. By the end of the 20th century, major breakthroughs in the radio frequency area resulted in a drastic change in mobile and internet communication among users. Up until the 1980s, there weren’t many wireless devices available to common consumers, leaving them only for military operations. The tests carried out on these devices were abiding and time-consuming and they were used to ensure almost flawless operations for radar application purposes.

In the 1990s RF technology expanded among the consumer market in the form of phones, both cordless and wireless. Nowadays, it is extremely difficult to provide an efficient testing methodology that can accurately separate adequate and defective parts to obtain a reliable result.

Testing RF can be done in many different ways, depending on how the company or customer prefers it. Here we’ll be focusing on the most important way to test radio frequency in environmental conditions, which is thermal vacuum chambers.

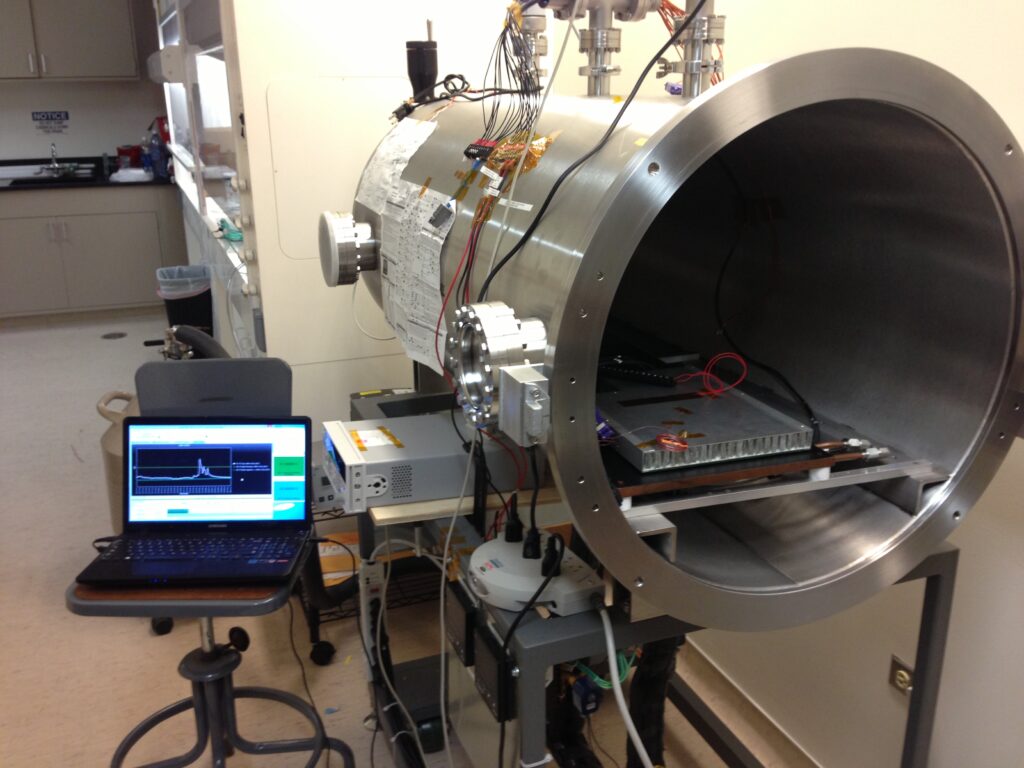

Thermal vacuum chambers

A thermal vacuum chamber is mainly used to mimic space conditions. The machine is able to do this process by using pressure and temperature. The vacuum can be used for months just to test if a spacecraft would be able to sustain space conditions. Custom Microwave goes into detail about the overall function of these chambers.

The spacecraft usually undergoes three primary vacuum tests: primary outgassing, survival in an airless environment, and finally thermal vacuum testing. These tests ensure a safe launch without any leakage of air or additional problems.

Apart from vacuum tests, these chambers also check high or low-temperature survival.

The thermal system of the chamber

The craft in question or testing usually undergoes a thermal test ranging from +100°C to -100°C and a vacuum seal of 10-6 mbar. While this check is active, radiofrequency waves should be transmitted through guide waves.

For the chamber to sustain high or low temperatures, engineers typically make them by combining aluminum, titanium, copper, and brass. There’re a lot more metals and components used, but these are some of the most commonly added.

Fails and errors are common on a spacecraft, so it’s no surprise why these tests take a long time to approve. The problems can be systematic or random, most occurring are heat loss from gas conduction, thermal conduction loss through leads, failing the test after taking out the spacecraft from the vacuum chamber, and many more.

All of these errors can’t be completely fixed, but can be modified to an extent.

Outputting power

This is the most common transmitter measurement for radiofrequency. Calibrating the measurements will allow you to see the device’s system health. They take many forms depending on the design and function.

Engineers use a device called an RF power meter to calculate the exact needed measurements. This instrument can’t measure phase, which is why mismatch resistance should be decreased so it would interfere less with the signal that engineers calculate. The extent of the power meter is around 50 and 70 dB. RF power meters on a more high-end quality can measure unified power and cause pulsed RF power.

Apart from the power meter device, a spectrum analyzer can be used for the same purpose. This instrument has more precision in calculating measurements but in more a complex way. The device is very precise and accurate. Calibrating the device’s measurements will show it’s accuracy is bigger than 100dB

With an ability to correct mistakes and precision in the calculation, vector networks, and signal analyzers calculate significance and process.

Interfering signals

It is ideal to only register the signal that is required when measuring radio frequency signals, but other signals can interfere. Spurious, harmonic, or intermodulation are some of the indications. Harmonic signals, because of their frequency, are more available. It can normally be found at 1 GHz, but it can be found at different ranges as well.

Every interfering signal is also known as spurs. They can show up at any frequency or power. Because they’re so unpredictable, it is harder to remove them from calibrating the correct signals. But empirical methods can help reduce and minimize their impact.

The accuracy of interfering indications can be measured using both spectrum analyzers and vectors. In a radio frequency transmitter, these interfering signals mean wasted radio frequency power that didn’t go into the specified transmission. This can lead to reduced productivity, reduced battery life, and test yields.

Channel power

Radiofrequency broadcasters are handled to protect and send information in order for consumers to use a particular spectrum and to improve its effectiveness. The unified power across the channel is power-in-a-band or often referred to as occupied bandwidth. It has the role of the integrated power to start and stop the frequency.

ACP is a measure used to evaluate the density of integrated power within the channel or occupied bandwidth.

Quality modulation

Radiofrequency transmitters contain data for modulation carriers. Looking over the modulated indication can tell a lot about the transmitter chain.

The actual value of the inflection is defined by IQ waveforms and error vector magnitudes. You can measure the accuracy and phase of the signal’s magnitude by using a vector signal analyzer. The importance and phase of the waveform are calibrated after each cycle on the symbol clock and then translated into IQ parts and compared with the intended value of the elements.

In conclusion

In several applications and RF transmitters, all of the tests mentioned above for radio frequency testing are widely used. If you are thinking of making a wireless system or a wireless component, checking the radio frequency is necessary for a lot of states. There are basic guidelines you need to obey and these measures can be of great help in order to measure anything. All tests should be used with caution and with a strategy that can maximize any radio frequency transmitter’s efficiency and accuracy.