The Vienna-based Cubicure has announced the first flame-retardant material developed for SLA 3D printing. The flame-retardant photopolymer Evolution FR is designed for 3D printers with implemented Cubicure’s patented Hot Lithography technology.

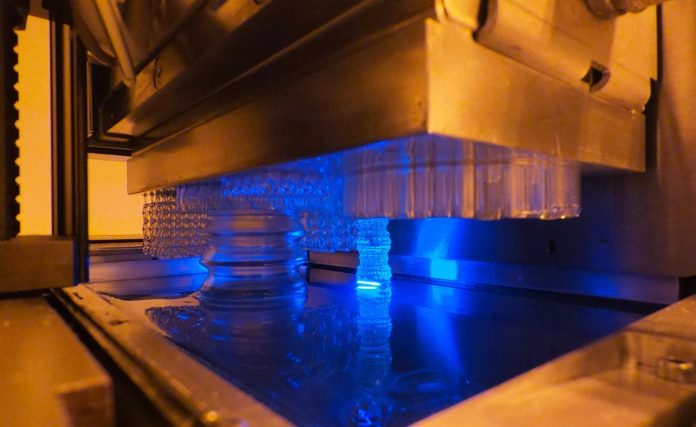

The new material called Evolution FR (Flame-retardant) is based on tough methacrylate photopolymer Evolution, which is developed especially for the patented Hot Lithography technology. This technology is similar to the conventional stereolithography but involves the use of highly viscous photopolymer resins for improving the physical and mechanical properties of final 3D-parts.

According to Cubicure, Evolution FR complies with the UL94 V0 standard, which means that any burning of the material would be extinguished within 10 seconds with no inflamed drops. The use of halogen-free products makes the material less harmful in terms of fire toxicity. To date, such properties could only be found in polymer materials for such 3D printing technologies as filament extrusion (FDM/FFF) or powder sintering (SLS).

The company expects that the patented additive technology along with specialized materials will allow approaching possibilities offered by conventional injection molding. The new flame-retardant photopolymer resin can be applied in the transport sector and electronics market, where flame-retardant properties of used materials fall under strict regulations.

Cubicure is not the only company to present new 3D printing materials this month. Chemical company Huntsman also unveiled several materials: TPU-based resin IROPRINT R 1801 and TPU-based filament IROPRINT F 80112. Huntsman already offers a wide range of 3D printing consumables for HSS, DLP, SLS, SLA, and FFF printing. Flexibility and toughness of the new materials will allow them to stay on par with already existing ones.

As a matter of fact, IROPRINT F 80112 is said to be the softest and the most flexible filament ever offered by Huntsman. It’s said to perform phenomenally when it comes to printing rubber-like materials, such as shoe soles.

In its turn, IROPRINT R 1801 demonstrates great strength and elasticity. This polyurethane-based resin is optimized specifically for DLP and SLA 3D printing, as well as other technologies that involve curing with radiation. This material would be perfectly suited for the printing of footwear since it has great elastic properties and can provide high-quality object surface.

“Traditionally, urethane-based 3D printing materials are stiff and brittle, and largely aimed at prototyping projects or small-scale tasks. IROPRINT materials are different. Soft yet strong, and offering specific properties such as high rebound, they are optimized to help increase the adoption of 3D printing in mass manufacturing applications,” said Stephane Peysson, Global Business Development Manager at Huntsman Polyurethanes. “As we continue to build our ecosystem of 3D printing partners, we look forward to talking to key players in the global additive manufacturing community at Formnext and explaining what our IROPRINT product platform has to offer.”

The Evolution FR photopolymer will be presented on the 19th-22nd of November at Formnext 2019 in Frankfurt. If you’re interested in buying a 3D printer, but don’t know where to start, check out this guide (https://top3dshop.com/blog/3d-printer-buying-guide), it’ll help you find the printer that’s best for you!