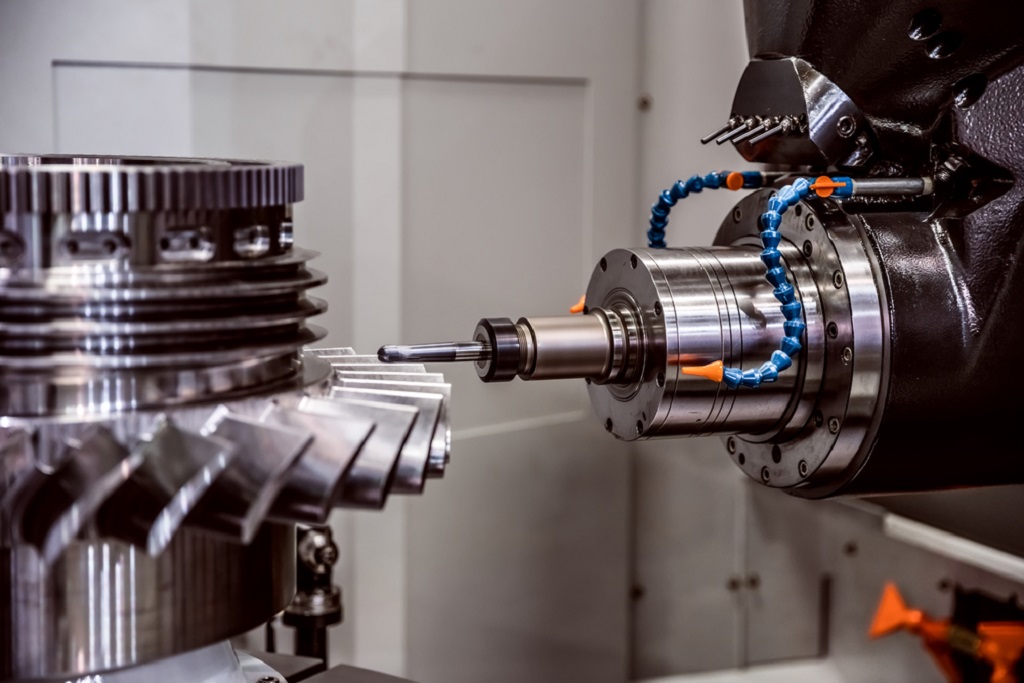

Milling machines, the workhorses of modern manufacturing, play a pivotal role in transforming raw materials into usable parts and products. Their ability to cut, shape, and drill materials with precision has made them indispensable in various industrial domains. This article endeavors to shed light on the myriad applications of milling machines, and how they contribute to the operational efficiency across different sectors.

Core Functions of Milling Machines

The central essence of machines lies in their multifunctionality and precision. Here’s a glimpse into their core operations, delving into the primary question: what is milling used for?

- Cutting and Shaping: machines excel in carving intricate shapes and designs out of solid materials such as metal, wood, or plastics. Their cutting prowess ensures that materials are shaped to the exact specifications required.

- Drilling: They have the capability to bore holes with pinpoint accuracy, making them indispensable for operations requiring precise drilling.

- Finishing: By smoothing out rough edges and surfaces, machines contribute to the final touch of products, ensuring they are ready for use or further processing.

Delving into Specific Milling Techniques

Grinding machines come in various types, each designed for specific tasks. Understanding these can help harness their full potential:

The Efficacy of Ball Mills: What is a Ball Mill Used For?

Ball mills stand out in the domain of grinding and mixing materials like ores, chemicals, and ceramics. Their applications include:

- Particle Size Reduction: They are instrumental in grinding materials to finer particle sizes, which is crucial in many industrial and chemical processes.

- Material Mixing: Through efficient mixing mechanisms, they ensure a homogeneous blend of different materials, facilitating better product quality.

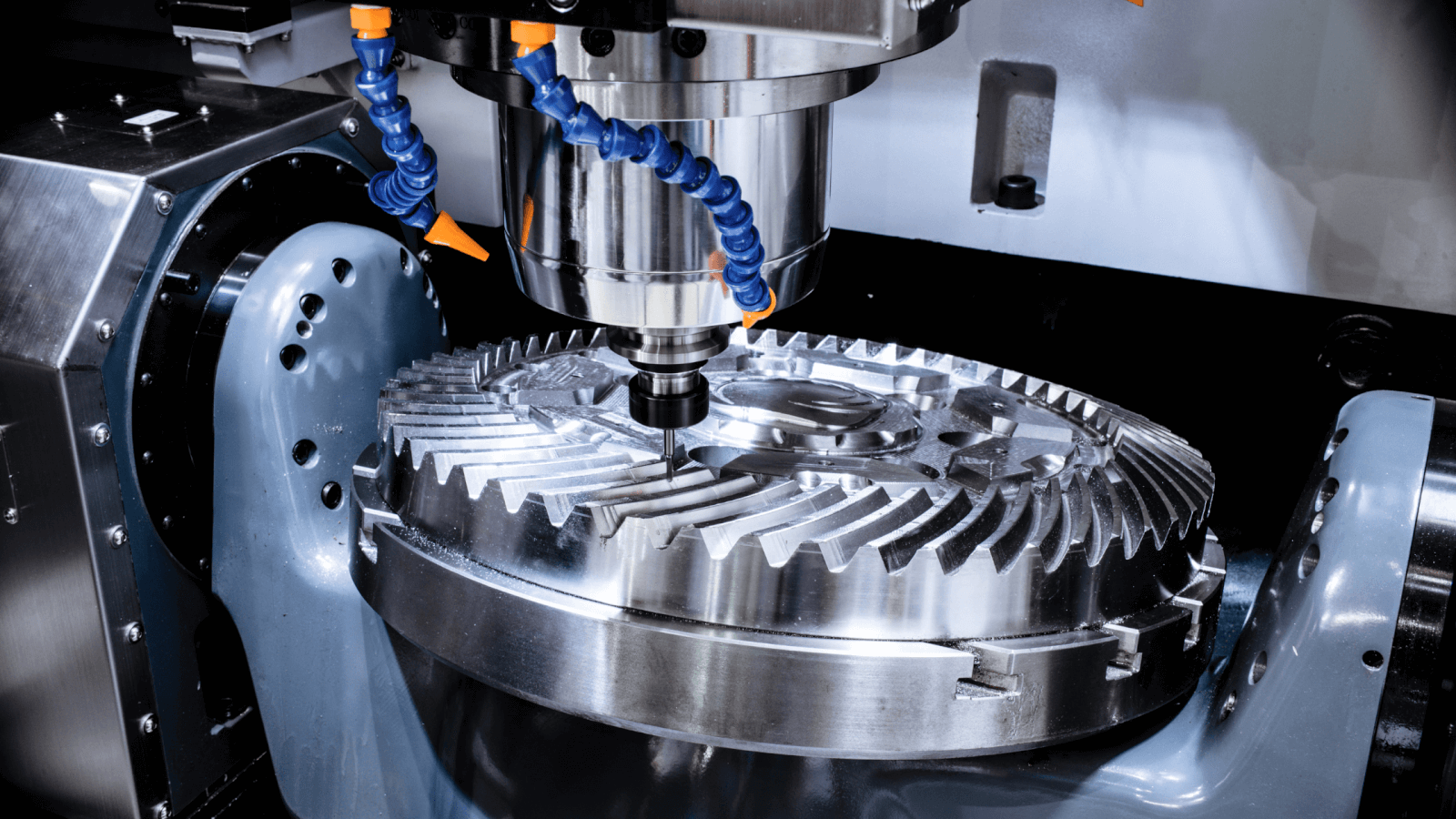

The Horizons of Horizontal Milling

Horizontal machines, known for their horizontal spindle orientation, offer a distinct set of advantages:

- Heavy Material Removal: Their structure facilitates faster and more efficient removal of material, making them suitable for heavy-duty tasks.

- Slot and Keyway Cutting: The ability to cut slots and keyways with precision makes them a preferred choice for many industrial applications requiring these functionalities.

With these capabilities, it’s clear to see what a horizontal milling machine is used for in various industrial scenarios.

Allwin Manufacturing Overview

Allwin, a leading manufacturer in the milling machines’ domain, offers a broad spectrum of milling solutions catering to diverse industrial needs. A tour on their website, allwin-grinding.com, unveils a range of machines from laboratory grinders to robust machinery for heavy industries.

Allwin’s machinery is tailored to a variety of sectors, demonstrating versatility and precision:

- Laboratory Research: Precision grinders aid in research and development activities.

- Battery Production: Enhances cell production and battery composition.

- Ceramic Industry: Produces finer ceramic powder, giving a competitive edge.

- Pharmaceuticals: Grinds particles to nanometer fineness for precise drug dosing.

- Food Processing: Ensures consistent food processing with automated grinding systems.

- Cosmetics: Facilitates the creation of diverse cosmetic products like creams and sunscreens.

Concluding Remarks

The realm of grinding machines is vast and versatile. They have significantly contributed to the advancement of modern manufacturing by ensuring precise cutting, shaping, and drilling of materials. The different types of milling machines, each with its unique set of capabilities, cater to a broad range of industrial applications. With industry leaders like Allwin continuously innovating, the future of grinding machinery is geared towards more enhanced performance, reliability, and versatility, thereby promising to further elevate the standards of manufacturing and production processes.