Biogas production is becoming increasingly popular as a sustainable energy source. To optimize biogas yields, incorporating advanced technology is crucial.

One such technology is the use of devices that provide a steady supply of oxygen. These systems enhance the efficiency and output of biogas plants by ensuring a consistent oxygen supply.

Understanding the role and benefits of oxygen generators for biogas are essential for anyone involved in this field.

These devices are designed to provide the precise amount of oxygen required, thereby boosting the overall productivity and stability of biogas production processes.

By integrating these systems for biogas, plants can achieve higher efficiency and more reliable output.

The Role of Oxygen

Oxygen plays a vital role in the bio production process. During the initial stages of anaerobic digestion, a small amount of oxygen is necessary to kick-start the bacterial activity that breaks down organic matter.

This initial aerobic phase helps in the faster breakdown of complex organic compounds, paving the way for more efficient anaerobic digestion later.

By ensuring the right amount of oxygen is present at the start, bio plants can significantly improve the overall efficiency of the digestion process.

Benefits of Using Oxygen Generators

Utilizing these systems offers several advantages:

- Enhanced Efficiency: By ensuring a controlled supply of oxygen, these systems optimize the aerobic digestion phase, leading to higher yields. This means that more biogas can be produced from the same amount of organic material, improving the overall efficiency of the process.

- Improved Stability: A steady oxygen supply helps maintain stable conditions within the digester, reducing the risk of process disruptions. Consistent oxygen levels ensure that the bacterial communities involved in biogas production remain healthy and active, which is crucial for continuous and stable biogas output.

- Increased Methane Production: Proper oxygenation improves the breakdown of organic matter, resulting in higher methane concentrations in the produced biogas. Methane is the primary component of biogas, and higher concentrations mean more energy can be extracted from the biogas produced.

- Reduced Odor: Efficient aerobic digestion can significantly decrease the odor associated with production, making the process more environmentally friendly. By minimizing unpleasant smells, plants can operate in closer proximity to residential areas without causing disturbances.

- Energy Savings: By optimizing the digestion process, these systems can lead to lower energy consumption in plants. This not only reduces operational costs but also enhances the overall sustainability of the production process.

Types of Oxygen Generators

There are several types of systems available, each suited to different scales and requirements of production:

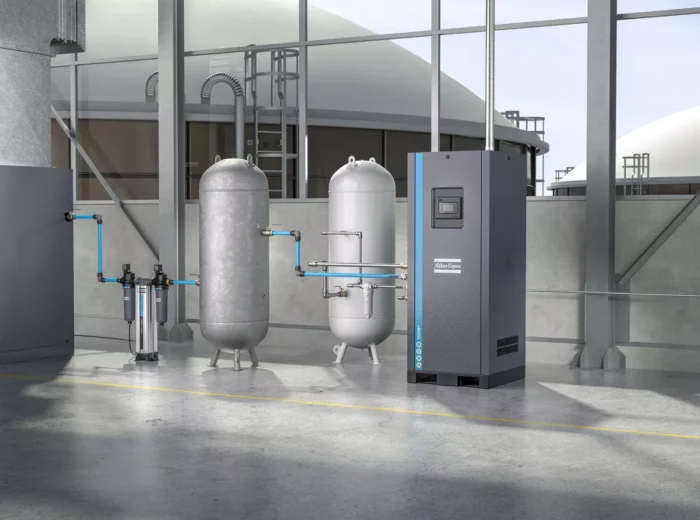

- Pressure Swing Adsorption (PSA) Systems: These are widely used for their efficiency and reliability. They work by adsorbing nitrogen from the air and releasing high-purity oxygen. PSA systems are known for their robustness and ability to provide a continuous supply of oxygen, making them ideal for large-scale plants.

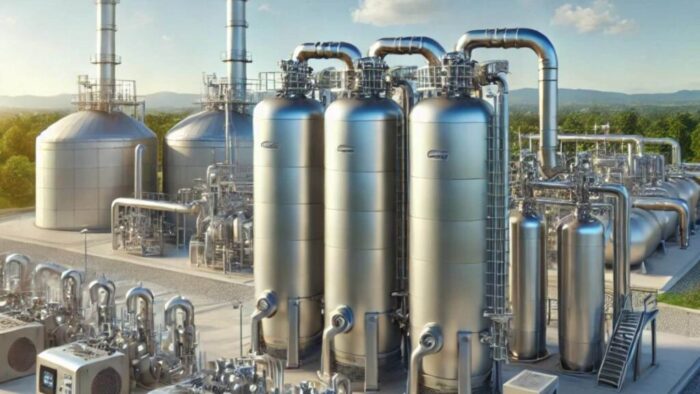

- Vacuum Pressure Swing Adsorption (VPSA) Systems: Similar to PSA systems but operate at lower pressures, making them energy-efficient and cost-effective for larger operations. VPSA systems are particularly suitable for plants that require large volumes of oxygen but need to keep energy consumption in check.

- Membrane Systems: These use selective permeable membranes to separate oxygen from other gases. They are compact and ideal for smaller plants. Membrane systems offer flexibility and are easy to install, making them a popular choice for producers with limited space or budget constraints.

Maintenance and Care

Proper maintenance of these systems is crucial for their longevity and performance:

- Regular Inspection: Periodically check the components for wear and tear. Regular inspections can help identify potential issues before they become major problems, ensuring the system operates smoothly.

- Filter Replacement: Replace filters as recommended by the manufacturer to ensure optimal air quality and performance. Clean filters prevent contaminants from entering the system, which can affect its efficiency and lifespan.

- Calibration: Regular calibration ensures the system produces the correct oxygen concentration. Accurate calibration is essential for maintaining the right balance of gases in the biogas production process.

- Cleaning: Keep the system clean and free from dust and debris to maintain its efficiency. Regular cleaning can prevent blockages and ensure that the system continues to operate at peak performance.

Integrating Oxygen Generators

Integrating these systems into existing plants requires careful planning and implementation:

- Assessment: Evaluate the specific needs of the plant, including the required oxygen levels and production capacity. A thorough assessment helps determine the most suitable type and size of the system.

- Installation: Ensure proper installation by trained professionals to avoid any operational issues. Professional installation guarantees that the system is set up correctly and safely, minimizing the risk of malfunctions.

- Monitoring: Continuously monitor the performance of the system and its impact on biogas production. Regular monitoring helps track the effectiveness of the system and allows for timely adjustments if needed.

Choosing the Right Oxygen Generator

Selecting the appropriate system for a plant involves considering several factors:

- Capacity: Ensure the system can produce the necessary amount of oxygen for the plant’s size and production goals. Choosing a system with the right capacity is crucial for meeting the oxygen demands of the production process.

- Efficiency: Look for systems with high efficiency and low energy consumption to maximize cost savings. Efficient systems reduce operational costs and enhance the overall sustainability of the plant.

- Durability: Choose a system built with robust materials that can withstand the demanding conditions of production. Durable systems offer long-term reliability and minimize the need for frequent replacements.

- Support and Service: Consider the availability of technical support and maintenance services from the manufacturer. Reliable support ensures that any issues with the system can be quickly addressed, minimizing downtime and maintaining productivity.

Cost Considerations

While the initial investment in these systems may be significant, the long-term benefits often outweigh the costs.

Enhanced biogas yields, improved plant stability, and reduced energy consumption contribute to a faster return on investment.

Additionally, many suppliers offer financing options or leasing arrangements to make the technology more accessible to biogas producers.

It’s important to factor in these long-term savings and potential financing solutions when evaluating the cost of these systems.

Environmental Impact

Incorporating these systems into biogas production not only improves efficiency but also has positive environmental effects.

By optimizing the digestion process, these systems help reduce greenhouse gas emissions associated with biogas production.

Additionally, the reduced odor and improved waste management contribute to a cleaner and more sustainable operation.

These environmental benefits align with the goals of many biogas producers to create greener and more sustainable energy solutions.

Case Studies and Success Stories

Numerous biogas plants worldwide have successfully integrated these systems, resulting in significant improvements in their operations.

For instance, a biogas plant in Germany reported a 25% increase in methane production and a 15% reduction in energy consumption after implementing these systems.

Similarly, a facility in India achieved a substantial decrease in operational disruptions and maintenance costs, enhancing overall productivity.

These success stories highlight the tangible benefits that these systems can bring to biogas production.

Future Trends and Innovations

The technology behind these systems continues to evolve, with ongoing research and development aimed at further enhancing their efficiency and effectiveness.

Innovations such as smart control systems, which automatically adjust oxygen levels based on real-time data, are being explored.

These advancements promise to make biogas production even more efficient and sustainable in the future.

As the biogas industry grows, continued innovation in oxygen generation technology will play a crucial role in meeting increasing demand and improving overall process efficiency.

Conclusion

Oxygen generators are a vital component in enhancing the efficiency and stability of biogas production.

By providing a consistent supply of oxygen, these systems help optimize the anaerobic digestion process, leading to higher biogas yields and improved plant performance.

Proper maintenance and integration of these systems can significantly benefit biogas plants, making them more productive and environmentally friendly.

Investing in the right system, tailored to the specific needs of a biogas plant, can lead to substantial long-term benefits, both economically and environmentally.