The printed circuit board is a component without which we couldn’t imagine modern technology. Without PCB, the functioning of most of our devices would be impossible. In today’s technology era, PCBs are very significant pieces of hardware-tech. Today, their presence is almost inevitable in the life of a modern human.

The Evolution Of PCB

Its history goes back to the 1900s and it’s connected to a German inventor, Albert Hanson. Hanson was working on a flat foil multi-layered conductor. The conductor was supposed to be implemented to an insulating board. On the other hand, Thomas Edison also gave his contribution. It was while he was working on chemical-based plating conductors.

However, the history of modern PCB started with an Austrian engineer Paul Eisler. Eisler has invented a printed board which was a part of a larger radio set project. PCB technology was first used during World War II. It was used for military purposes without commercial use. After the war, it was being released for civilian use. That was the beginning of the commercializing of PCBs.

Today, this technology is still evolving. Large investments are directed into their further development. Some new-age PCB improvements include adopting artificial intelligence, better materials, automation, etc. According to pcbonline.com, this is the technology with great development potential. Therefore, it is of significant interest to researchers and manufacturers.

Printed circuit boards are highly-developed and versatile. Emerging new-tech trends and consumer needs have a huge impact on the PCB market. That includes both – using and manufacturing. These are some of the major PCB tech trends. They will keep the PCB market sustained for quite some time…

1. Miniaturization And High-Density Interconnection

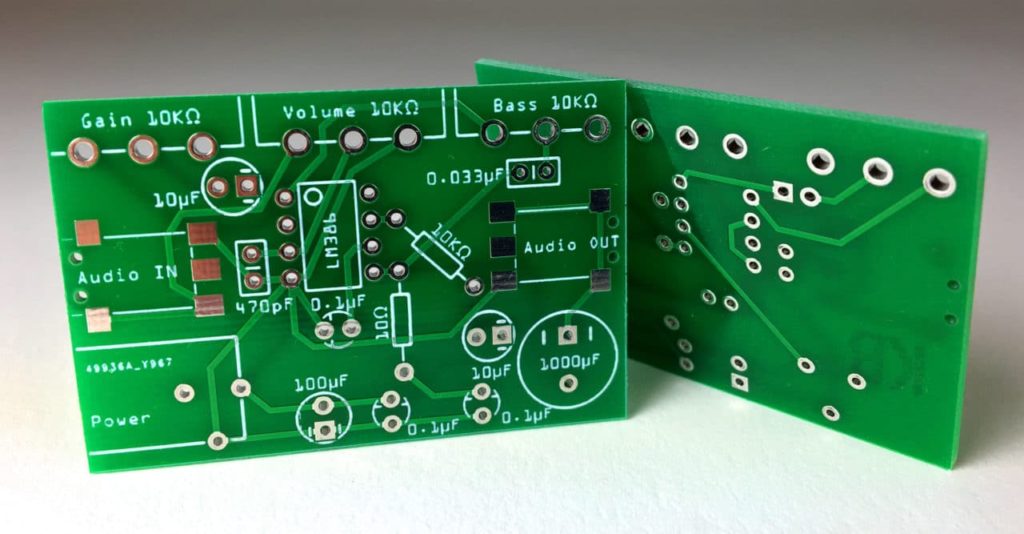

Nowadays, consumers are striving toward smaller dimensions. Therefore, miniaturization assumes smaller and more efficient devices. Since PCBs are a basic component in most of the new-tech devices, they must also be affected with miniaturization. This also refers to high-density interconnect technology. Especially when it comes to PCB market. It is expected that additional processing will reduce PCB size down to just 4 mm. Fascinating, isn’t it?

2. Greener Manufacturing And Using The Advanced Materials

Like many other products, PCBs need to keep up with ecologically sustainable production. When it comes to industry standards and legislation, PCB manufacturers are under pressure. A good example is the introduction of lead-free rollouts. They require more energy-intensive manufacturing processes. Therefore, the industry must find out a new manufacturing balance. On the other hand, PCBs are also made with fiberglass. Fiberglass is considered an eco-friendly material. Future advancements may also give place to some other materials with a higher rate of data transfer. The manufacturing will, most likely, continue with reconciling to planet changes.

3. Computing And Wearables

PCB technology already allows thinner boards and gaining functionality. It is mostly because today, there are a lot of practical devices using ever-smaller boards. We may even say that consumer electronics is the main driver of PCB manufacturing. Nowadays, wearables have also entered this industry. It is expected that PCBs will be alongside.

4. The Medical Care Implementation

The rapid medical technology development also influences PCB development. Board cameras are one of those examples. Today, we have cameras that should be swallowed or otherwise inserted into a human body. In that sense, the smaller cameras are the easier it will be for us.

As for other types of implementation…

PCBs are also implemented into public oversight. Many new technology devices containing PCB showed their usefulness. Lots of mobile companies also research how to provide even smaller cameras, etc.