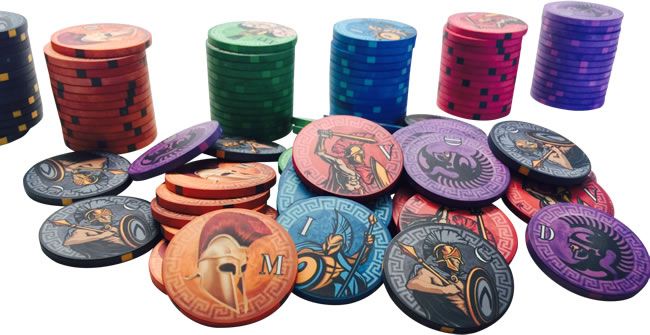

If you are a naturally curious person and have been gambling for a while, you must be wondering how the real casino and commercial poker chips are made. Your curiosity is very natural because the poker chips vary in size and color.

The texture and design are also different, which leads us to question how they are made. So in this article, we have decided to take you into the world of how the pieces are made. We will tell you details of the manufacturing methods.

What is the Difference Between Real Casinos and Commercial Poker Chips?

Before we jump into the manufacturing methods, we need to understand the difference between commercially available poker chips and those in real casinos. The main difference is that commercially available chips are there for sale by anyone who is interested.

On the other hand, real casino chips are made with a specific compression method that initially used clay. However, the clay pieces were subject to counterfeiting, and now casinos use a combination of plastic and clay. You can find more information on GambleUSA.com.

How are the Poker Chips Made?

There are many different types of poker chips that vary on the basis of size, design, and availability in the market. There are two primary methods of manufacturing both casino and commercial pieces. These are as follows:

- Injection molding processes create uniformly designed chips that do not vary in files and have standard color and texture.

- The compression and molding of clay is the second method that offline casinos initially used. However, pieces made only from clay are no longer used because a composite between plastic and primary material prevents counterfeiting.

What are the Types of Poker Chips?

There are four main types of poker chips available in real casinos and commercial markets.

1. Plastic

Plastic chips are highly prevalent in a commercial scenario because of their lightweight. These were the most common options available across groceries stores and other retail outlets.

Since plastic is easy to color, it was available in blue, red, and white as well as others. These were used mainly by people who wanted to play for fun in an informal setting. These kinds of pieces were so prevalent that anyone who played poker had them in their house and cabin.

2. Clay or Composite

If we are talking about the feel and texture of poker chips, clay was a better alternative than plastic. Initially, these pieces were made out of clay with the method of compression. Over time, casinos made the switch to a composite material which included ABS plastic and clay.

These were made by compression and started replacing plastic pieces. While the products made of clay have not been in use for a long time, composite options are still being used in real casinos.

The benefit of composite pieces over clay once is that they are not written and are more durable. The weight varied in the range of 11 to 13.5 ounces.

They facilitated the game and gave a good feel making a deeper sound when it hit the table. Now, they are commercially available, and you can even find them in retail stores. They are relatively inexpensive and worth buying for any player who wants to own a decent set.

3. Ceramic

If you love the clinking sound of ceramic, then these chips will appeal to you. Ceramic is used in the injection molding process for a smoother finish and defined texture.

It also has better quality than the clay and plastic counterparts. Ceramic and general are of better durability than both composite material and plastic.

In the process of injection molding any kind of branding and graphics can be directly printed on the surface without requiring an inlay of stickers.

Because injection molding is the primary manufacturing process, pieces made out of ceramic offer a wide variety of customizable options in different designs.

When it comes to sliding poker chips on a table, these offer them a better feel. These are used in commercial marketplaces as well as real casinos but are comparatively more expensive than the types mentioned above.

4. Metal

These are not as common as the other three options but can still be found in commercial markets. Ceramic and clay composite mainly dominate the market, but you can also find a metal set with a unique design.

If you find a decent set, it will be more likely a limited edition one, which will make it more expensive. The typical metals used to manufacture the sets came in bronze, silver, and gold shades.

5. The Modern Poker Chip

Today, you will find the modern poker chip in real casinos made from composite clay. This material becomes the most favorable one, ahead of ceramic, because of the price and the prevention of counterfeiting. In a modern piece, real casinos do not disclose how they are made.

We only have the information that compression molding or injection molding is used by casinos. But in what proportion the other materials are used in the composite material along with clay is not public knowledge.

The manufacturing process thus provides a level of security to real casinos and helps them keep the gaming as secure as possible.

The new formula of manufacturing is focused on durability, so the casinos save money by not having to manufacture pieces over and over again.

The modern alternative can withstand high pressure and temperature conditions and have an inlay of paper as well as an undetachable heat-resistant film. It also prevents duplication.

The Takeaway

The only prevalent methods in the manufacturing of real casino and commercial poker chips are injection molding and compression. How a particular material reacts to these two processes determines its composition.

Ceramic and clay are the most popular materials and are relatively more widely available in the commercial market.

Plastic pieces can be collected and relatively cheap, whereas metal sets will be difficult to find in commercial spaces and a real casino.